Cybersecurity in industrial environments is rarely visible or dramatic. Yet a large part of the German economy depends on it. Production lines, logistics chains and critical infrastructure are governed by Operational Technology (OT): systems designed for continuity and safety, not for a world in which cyber threats evolve on a daily basis.

That is where the tension lies. Many OT environments have grown organically over decades, combining legacy systems with modern IT and rarely designed with cybersecurity as a core principle. Keeping these environments secure is therefore not merely a technical challenge, but a strategic one.

Understanding Before Control

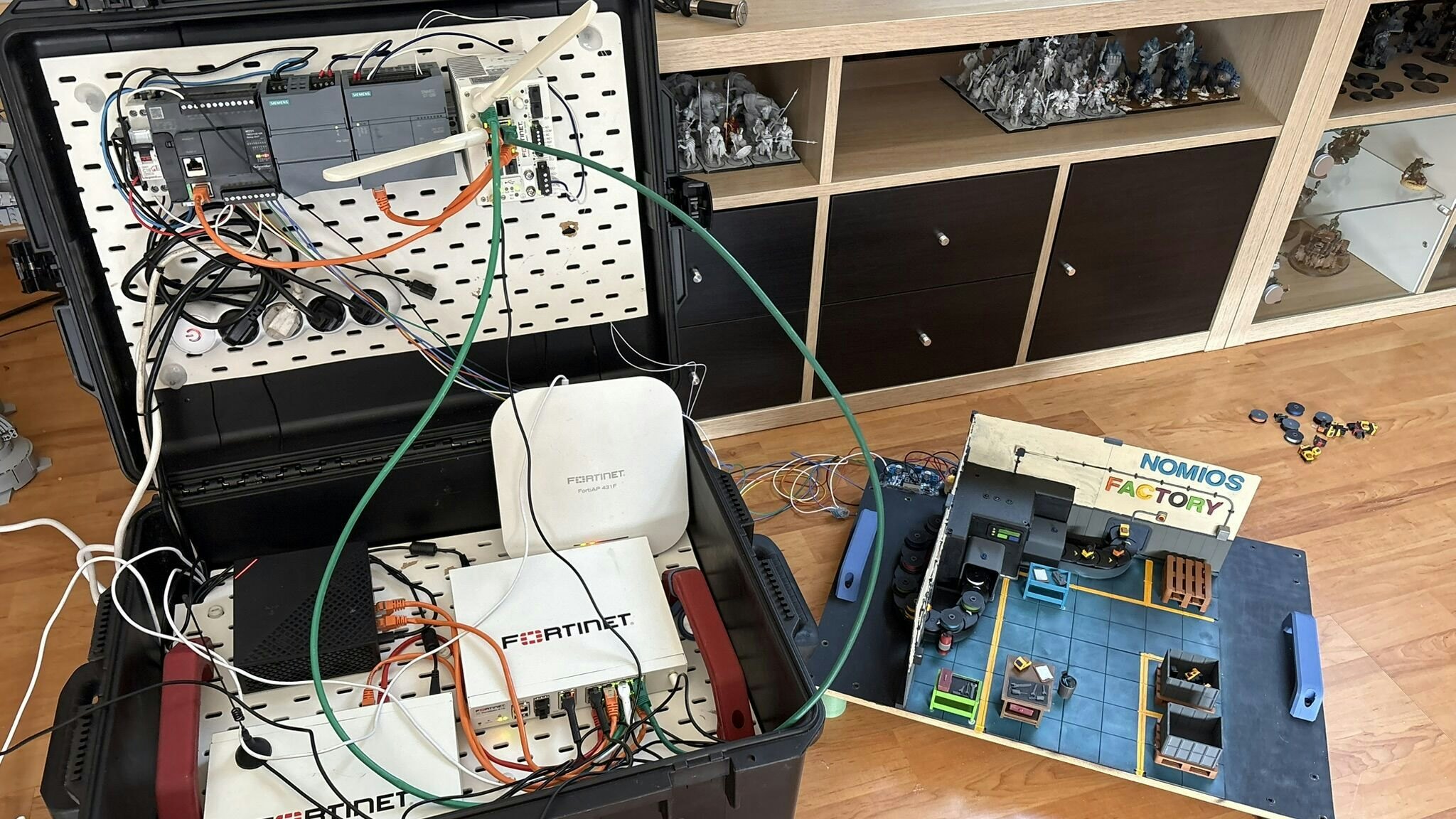

At Nomios, engineers in Germany have been developing an OT security lab in which commonly used industrial components are combined with security technologies from Fortinet, TXOne and other vendors. This is not a demonstration model, but a working environment. A place where attacks, failures and misconfigurations can be simulated without putting production at risk.

The premise is straightforward: effective OT security begins with understanding. Not through spreadsheets and policy documents, but by observing what actually happens when a protocol fails, a network segment is misconfigured or a detection rule triggers too late. In a lab, abstract threats become tangible reality.

An Unexpected Source of Inspiration

That conviction was recently reinforced by an initiative from colleagues in France. They too are building an OT/IoT security lab, but chose to take the concept a step further. One engineer combined two personal passions: building miniature worlds and cybersecurity.

The result was a miniature “Nomios OT Factory”. A physical representation of an industrial environment in which machines, processes and networks come together. Playful in appearance, but serious in intent. By reducing scale, complexity becomes easier to see.

A Cliché That Turns Out to Be True

Passion as a success factor may sound like a cliché, particularly in a field often associated with highly technical, pragmatic specialists. Yet anyone who has spent time in cybersecurity will recognise a recurring pattern. The engineers who make the real difference are rarely just executors. They are the ones who keep asking questions, who want to understand how something works and why it was designed that way in the first place.

In OT security, this is not a luxury, but a necessity. Every environment is different. Every production line has its own vulnerabilities. Standardised solutions are rare. That reality demands curiosity, creativity and a deep respect for industrial processes.

What This Means for Executives and Decision-Makers

For IT directors, CISOs and executives responsible for OT environments, cybersecurity has long since moved beyond the purely technical domain. It affects business continuity, employee safety and, ultimately, reputation and liability.

Labs such as those developed by Nomios are therefore not gadgets, but tools for dialogue. They make risks visible in practical terms and help clarify which decisions truly matter. Not to create fear, but to enable informed and realistic trade-offs.

Technology Is Essential, People Make the Difference

The photographs accompanying this article show industrial components, network infrastructure and OT-specific security technology. But they also reveal something else: craftsmanship. A willingness to look beyond specifications and use cases, and to place technology from Fortinet, TXOne and other vendors within the operational context in which it must function.

Perhaps that is the most important lesson. At a time when cyber threats are increasingly abstract, security ultimately remains a human endeavour. Driven by expertise, experience and—however clichéd it may sound—passion.

Our team is ready for you

Do you want to know more about this topic? Leave a message or your number and we'll call you back. We are looking forward to helping you further.